If you’re an oh-so-clever person who is set on making some soap on a rainy Sunday, and you’re between immersion blenders but your corded power drill and paint mixing attachment are right there in the kitchen because…reasons, you might think, “Eh, let’s try it! It worked on that canola-coconut liquid soap and traced in like 20 minutes. How bad could it be?”

The problem is, as a person with enough experience to be cocky but not enough to spot a problem on the horizon, you might also think, “Ooh, I’m going to whip up a 72% olive oil blend, just like Savon de Marseille!” Thank goodness you won’t have the hubris to think you’re actually making the real thing, and no way you’re going to triple mill ANYTHING the way they do in Marseille. But still, you’ll think that with your improvised tools you’ll get something soapy in, like, 20-30 minutes.

You’ll be wrong.

You’ll be wrong because you’ll underestimate how stubborn olive oil is to emulsify. You’ll be wrong because your notion of how fast a soap blending device should run will be off by a factor of ten. You’ll be wrong because you’re just clever enough to be blithe about a recipe that deserves respect.

After about an hour and a half you’ll be stooped over the bathtub with earplugs in, running the drill with one hand while searching “soap won’t trace” on your phone with the other. For a split second you’ll get a blistering case of Imposter Syndrome when your inner hater says, “I’ll bet no one else has ever been so stupid as to get stuck in the bathtub stirring a batch of olive oil soap that won’t stick because they mixed it wrong.” But then you’ll be like, um, no, EVERYBODY hates bringing soap to trace. It’s the first thing soapmakers complain about. And then you’ll remember why you like crafting so much: it all comes down to raw materials and first principles. If something goes wrong, you can probably repurpose it. And thousands of people before you have run into something similar and lived to blog about it.

At that point with your oil and lye well blended and a little thickened, you’ll call it good enough. You’ll pour some into molds and set them in the oven for “cold process oven process” to speed up the curing from 6 weeks to several hours, leaving the rest to slow-cure in a piece of PVC pipe. You’ll decide that if it all turns into a gooey mess, you’ll just melt it, add water, and have some very elegant bath gel.

Best of all, you’ll come away with:

Lessons Learned

Immersion blenders run A LOT faster than drills.

My drill is rated at 1350 RPM. Immersion blenders are easily ten times that fast, around 10,000-14,000 RPM or even higher.

Not much blender middle ground.

Soapmakers seem to use kitchen blenders or industrial blenders, without much in between. For a few years I’ve been considering getting a commercial immersion blender inspired by the sight of a chef blending a huge batch of black beans with a beast of a machine. But I haven’t run into many people using them for medium-scale production where I’d expect them to be popular, like people who regularly make hand-crafted batches. Anne Watson’s collection of reader-submitted reviews shows some soapmakers using their trusty kitchen-grade blenders every week for years on end, so presumably that should be good enough for my modest ambitions if I get the right one. I’m hesitant because I have indeed killed one blender already.

Temperature affects emulsion too.

I’d forgotten this, but blending too cool is one of the many factors that can slow things down. I didn’t experiment with reheating the mixture but I considered it.

Blend in a 5 gallon bucket (or bigger), for Pete’s sake.

I was trying to blend in a decent sized stainless steel soup pot because that’s the biggest non-reactive container I had on hand today. Because the pot was kind of short and the mixing shaft of the blending attachment was pretty long, I ended up with a lot of splatter. Fortunately I was wearing long pants for safety and they are now soaking in some white vinegar solution, but soaping is so much easier when you don’t have to deal with a lot of splatter. This is a good reminder to hit a homebrew or home improvement store and pick up a big bucket if I can’t find one in the basement. I’ve managed to blend successfully in short containers like a slow cooker but it’s really easy to make a mistake and lob caustic soap all over your counter.

If you have to splatter, use the bathtub or shower stall.

I was really stubborn and tried to wait out the blending in the kitchen, but I felt much better about the mess when I finally moved the operation to the bathtub. Cleaning up was really easy.

Palm oil raises eyebrows.

I have a lot of palm kernel oil from an order I made years ago before I was aware that palm kernel harvesting is harmful to ecosystems, animal populations, and people who depend on intact rainforests for their livelihood. Of course I’ll use what I have, but I won’t buy it again.

Soapmakers are incredibly generous with their expertise.

I’ve already linked to quite a few awesome resources throughout this post, but here are two more:

What’s Hot and What’s Not – A Study In Overheating – Auntie Clara’s Handcrafted Cosmetics

In this article, Clara gives a fascinating and detailed account of experimenting with different amounts of water in cold process oven process soaps. She describes some of her learning batches as “ugly”, but I find them full of character and very helpful to learn from. My takeaways were that she got the best results from batches with less water, blended to medium or thick trace as opposed to thin trace.

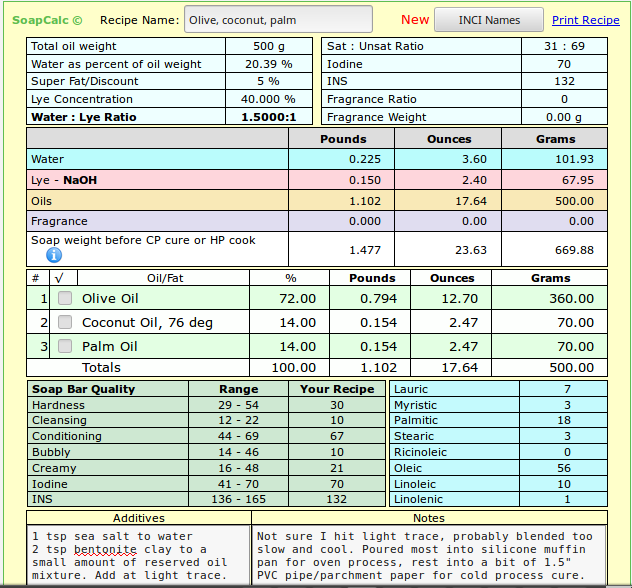

This super awesome classic tool lets you plug in ingredients and tweak parameters to generate a basic recipe. It’s wonderful for generating a recipe with the characteristics you want (Extra fat for mildness? Extra lye for cleansing? Wetter or drier? Etc.) and gives helpful information about the kinds of fats in your recipe, which you can use in turn to predict your soap’s characteristics and how long you’ll need to blend.

Here’s the SoapCalc output for the recipe I made. The main calculator does figure fragrance amounts for you but doesn’t do other additives. There’s a text field at the bottom for those. I added a teaspoon of sea salt to the water before adding lye, and mixed two teaspoons of bentonite clay into a little of the oil mixture and added after the recipe looked well-blended.

In conclusion….

So what will my soap end up like? I don’t know yet! I’m excited to find out and report back.

Update! The finished product.

Oof, this soap is ugly! has character! But honestly, it works great. It’s gentle with a good lather and smells subtle and pleasant.

The larger ones in this picture are the ones I cured in the oven. They were doing well for a while but at some point think the heat got too high and they bubbled up like muffins. It trapped air bubbles in the soap and made it look pretty weird. The smaller ones were the ones I molded in that bit of paper-lined PVC. They came out much prettier. I learned not to cut them with a knife because that wedges the pieces apart and can cause clumpy rips in the soap. The way to get nice smooth edges is to use a tool that cuts with a wire like a dedicated soap cutter or coping saw with wire instead of a blade, or something straight like a pastry cutter. I actually used a putty knife like you’d use for smoothing drywall and it worked well enough. Once again I’ve learned that making ugly, functional soap is pretty easy, but making gorgeous soap is quite a bit harder. Cold process soap takes patience but it seems like the best bet for getting reliably pretty soap.